Week 15: Mechanical Design

the assignment

This and next week is a group assignment only:

- design a machine that includes mechanism+actuation+automation

- build the mechanical parts and operate it manually

- document the group project and your individual contribution

brainstorming

First we spend some time brainstorming. Some weeks earlier I was really charmed with a Rose Engine. I figured we could make a simple version of it. David suggested engraving cheese with it. I'm not sure how, but our group ended up with the idea of making a Dutch Lunch Machine. I think we where inpired by the The queen of shitty robots. The Dutch Lunch Machine transports a 'boterham' along four stations with typical Dutch toppings like: 'hagelslag', 'muisjes', 'chocopasta' and off course 'peanut butter'.

My tasks

To be honest, I am not particularly satisfied with my contribution to this week. This week was about mechanical design and because of the type of machine that we chose: just one moving axis and given that we where with four people, I think my tasks where small. My job was to design the vertical parts of the stage and the upper horizontal part. And later on to draw the slots for the switches that defined the the end of the axis.

drawing part of the stage

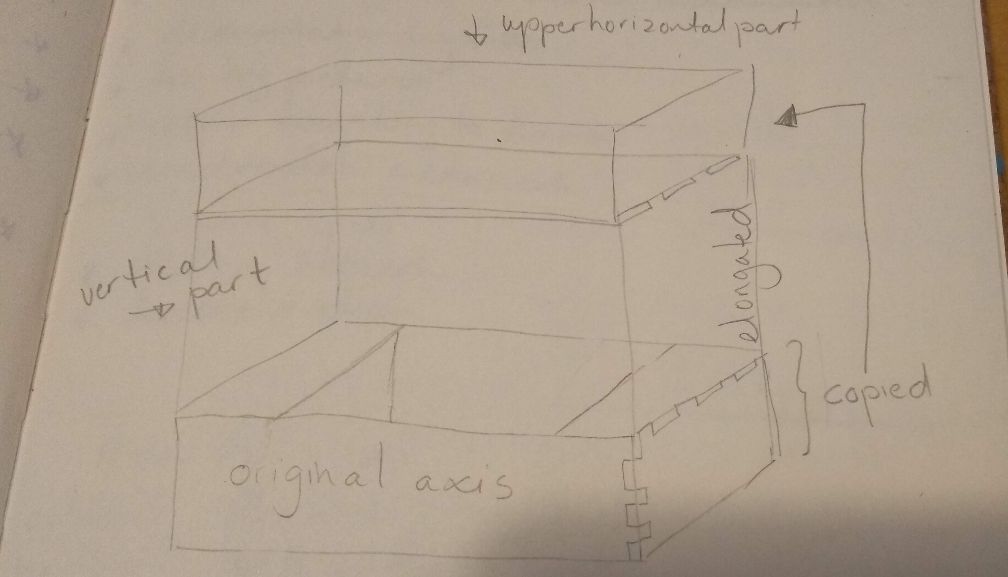

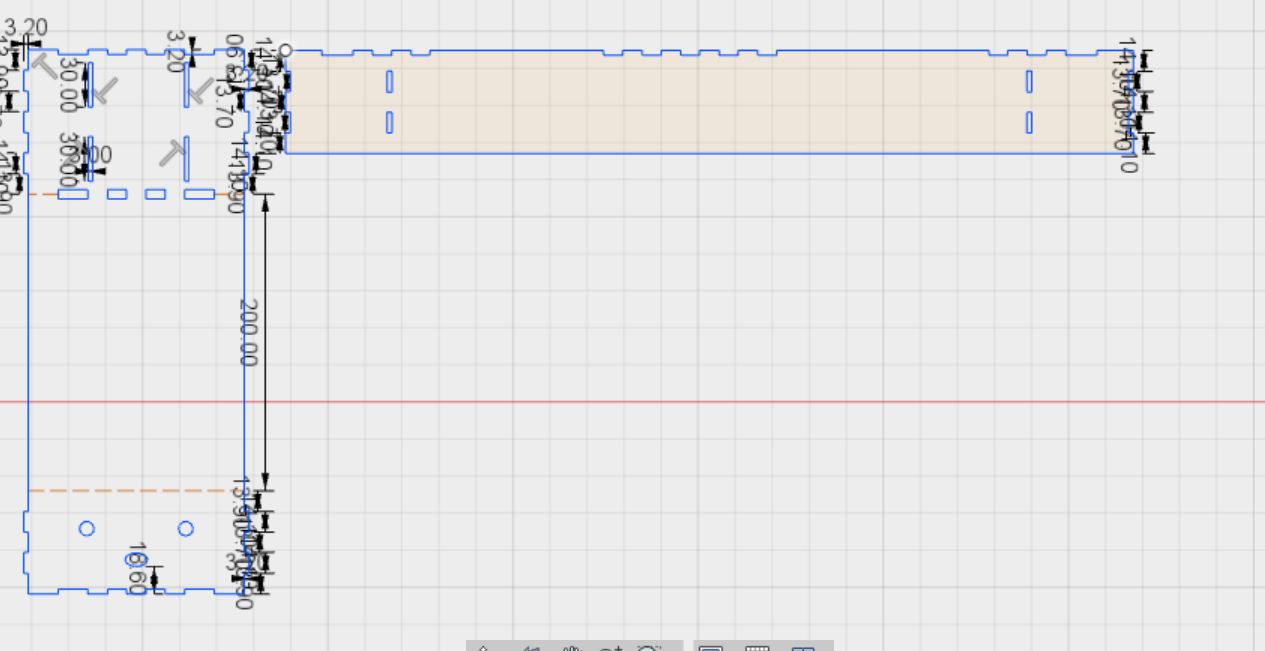

As a reference we used the files of the machine that Fab Lab Facens made in 2017. It included the drawings for the x-axis module we wanted to use. Johanna ran a test with different slot measurements with the laser cutter. When Hanna had arranged the dimensions we wanted, I used the file to draw the vertical parts and the upper horizontal part that holds the topping-dispensers. To draw the vertical parts of the stage I used original side panels and elongated them. To draw the upper horizontal part I copied the lower horizontal parts and drew the holes in that Hanna and Henk needed for their topping dispensers.

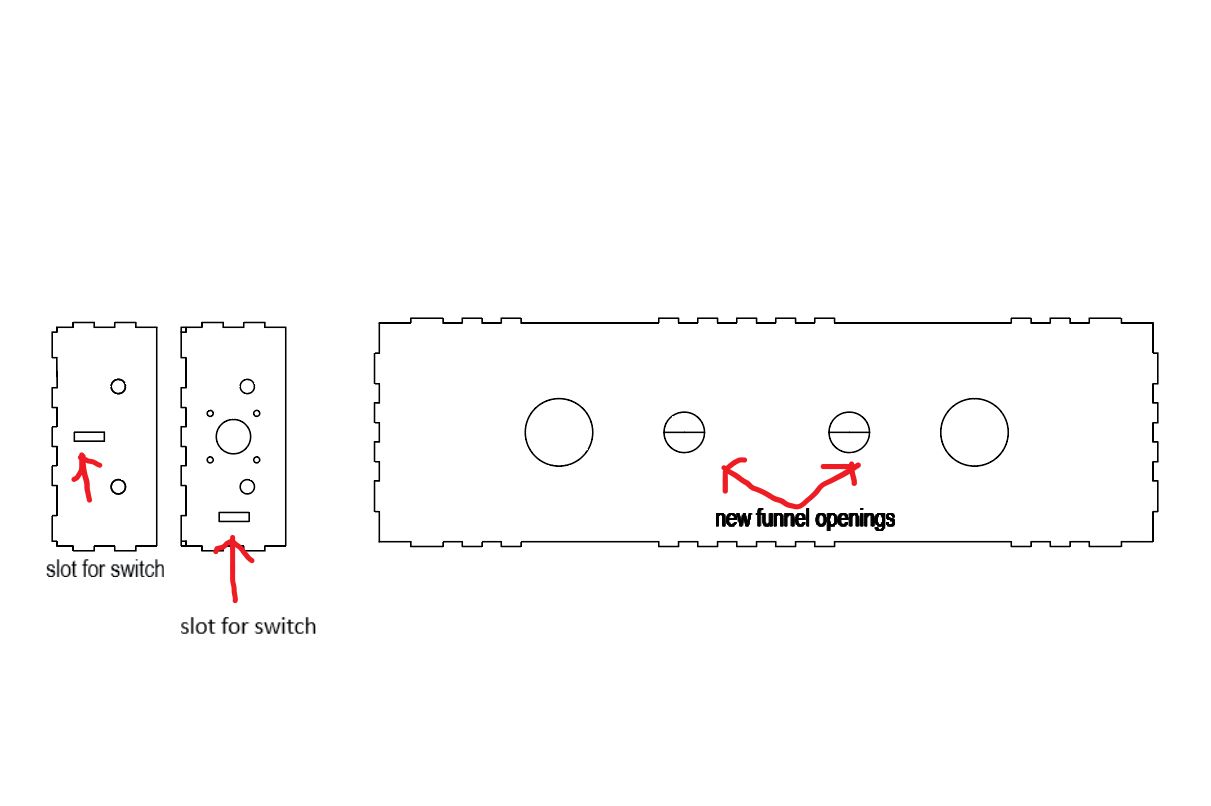

When I was drawing, we communicated via Slack. You can download the file with button underneath the text. Please keep in mind that it has a mistake in the slots of the vertical panels. They should me 3,2mm instead of 6,4mm. In the picture below you can see what is what. The parts that have comments on them in red are the ones I drew.

Fusion file my drawings for dutch lunch machine

At the beginning of week 16: Machine Design, we realized we needed two switches on each side of the X-arm, so we would have a stop signal for the motor to not turn further after that point. I made two slots for the switches in Fusion. Also we discovered that the holes in the funnels where to narrow for the sprinkles to go through. Hanna cut the funnels and attached plastic to it that she turned into a tube. I redrew the middle pannel so that these new tubes could go through. Cutting the holes for the tubes diametric at the same time gives you two half circles that Hanna can use as parts for the opening and closing of the funnels. The switches have a width of 6mm and a length of 20 mm. I drew exactly these dimesions, but I ended up sand papering a little so that the switches could fit in.

Fusion file slots for switches

Helping my team

For the documentation of the group proces I created a page and helped Hanna and Johanna with pushing their text and pictures to it. Also I helped Hanna with staying next to the laser cutter, so she could work on her documentation.